As a rapidly emerging short-distance personal transportation device in recent years, electric skateboards, with their advantages such as high flexibility and portability, have gradually become an important choice for urban commuting and leisure activities.

As the core component of an electric skateboard, the performance and design of the powertrain not only directly determine key indicators such as the product’s endurance, climbing performance, and top speed, but also profoundly influence the user’s control experience, equipment maintenance costs, and safety. These factors are the core defining factors of the electric skateboard’s product competitiveness.

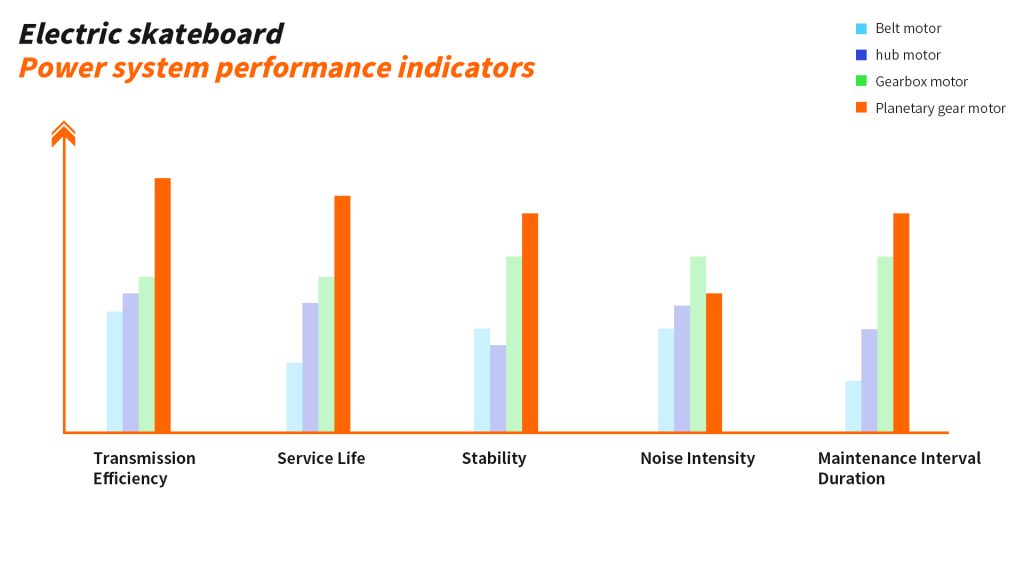

In the early days of the electric skateboard industry, powertrains primarily focused on basic functionality, resulting in two mainstream solutions: belt drives and in-wheel motors. Subsequently, some manufacturers experimented with transferring conventional gearbox motors, proven in low-performance applications like toy cars, to electric skateboards in an attempt to boost power output.

However, as user demands shifted from simply being functional to being user-friendly, durable, and aesthetically pleasing, the shortcomings of traditional powertrains in efficiency, reliability, and aesthetic integration became increasingly apparent.

For example, belt drives are susceptible to erosion from dust and rain, requiring frequent maintenance. In-wheel motors suffer from poor heat dissipation, resulting in insufficient climbing torque. Conventional gearbox motors are bulky, noisy, and their external structure presents a risk of collision.

These pain points are driving the evolution of electric skateboard powertrains towards greater efficiency, compactness, and integration. Since 2017, ECOMOBL has been pioneering a breakthrough in industry tradition, integrating a planetary gear structure, already well-established in high-end equipment such as aerospace, shipbuilding, and automotive, into electric skateboard powertrains.

This structural innovation addresses the multiple contradictions inherent in traditional solutions. This article, focusing on ECOMOBL’s internal planetary gear motor, systematically analyzes the technological evolution of electric skateboard powertrains, delving into the technical advantages and integrated design principles of the planetary gear structure, providing insights for industry-wide powertrain innovation.

Technological Evolution of Electric Skateboard Power Systems

The evolution of electric skateboard powertrains is essentially a process of “demand-driven technology selection.” From simple structures that initially met basic transportation needs, they have gradually evolved into high-performance structures that adapt to complex scenarios and provide a multi-dimensional experience. This can be clearly divided into three phases:

Belt and Hub Structures (2015 to Present): Early Solutions Oriented Towards Basic Functions

Around 2015, electric skateboards were in the development stage of the market. Users’ core demand was “electric drive,” with lower requirements for performance and user experience. Belt drive and hub motors became the mainstream choices in the industry due to their high technological maturity and controllable costs. However, the two showed significant differences in structural principles and performance:

Belt Drive Structure: a Transitional Solution Prioritizing Efficiency

The core principle of a belt drive is to connect the motor output shaft to the rear wheel axle via a belt. The friction of the belt transmits the motor power to the wheels. Typical examples include early Boosted Boards and other products.

Its advantages include:

- High transmission efficiency (ideally reaching 85%-90%), which effectively preserves the motor’s power output;

- Simple structure: The motor can be independently located below the board, requiring only belt replacement for maintenance, resulting in low costs

- High adaptability to motor speed: By adjusting the pulley diameter ratio, “speed reduction and torque increase” can be achieved, meeting basic climbing requirements.

However, as the usage scenarios become more complicated, the limitations of the belt structure are quickly exposed: first, the exposure of the transmission parts is the core shortcoming – the belt and pulley are in direct contact with the external environment, sand and dust can easily cause the belt to slip and wear, and rain can rust the axle. Users need to clean and replace the belt regularly (usually every 3-6 months), and the maintenance frequency is much higher than users expect; second, the belt tension is difficult to control accurately.

Excessive tension will increase the motor load and reduce efficiency. Too little tension will easily cause “loss of rotation” (that is, the motor rotates but the wheel set lacks power), affecting control stability; third, the belt drive has the phenomenon of “elastic sliding”.

Especially during sudden acceleration or climbing, the relative sliding between the belt and the pulley will cause power loss, the actual transmission efficiency is lower than the ideal value, and belt friction noise is easily generated.

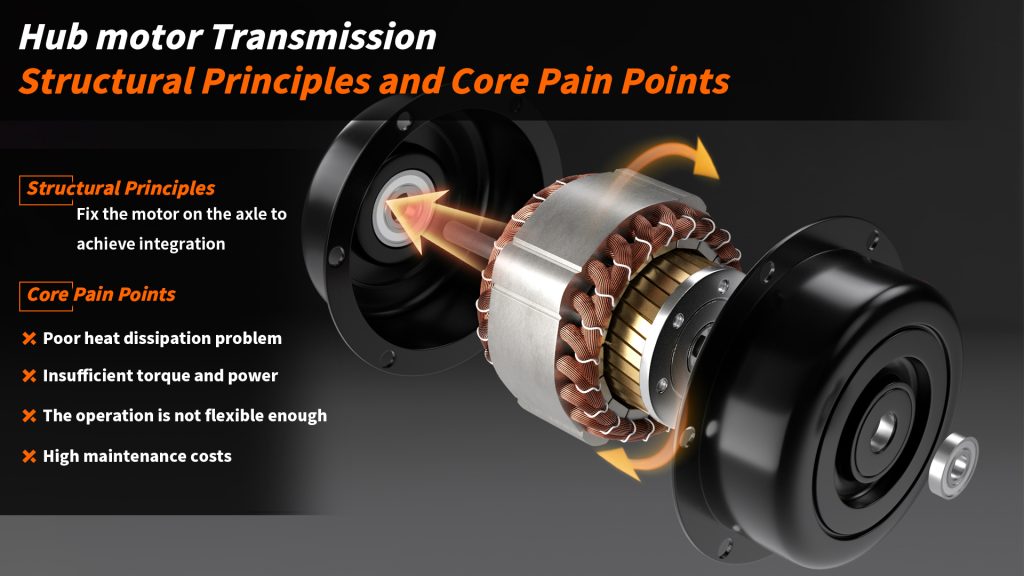

In-wheel Motor Structure: a Simplified Solution with Integration as the Priority

To address the issue of exposed belts, the in-wheel hub motor design emerged. Its core principle is to secure the motor stator to the wheel axle, integrating the rotor with the wheel housing. Rotating motors directly drive the wheels, eliminating the need for intermediate transmission components. This design is typically used in consumer electric skateboards like Xiaomi and Ninebot.

Its key advantages include:

- First, a highly integrated structure, with the motor and wheel integrated into one, eliminating exposed transmission components. This provides superior dust and water resistance compared to belt-based designs, significantly reducing maintenance requirements.

- Second, a simple design creates a cohesive wheel structure, better suiting the aesthetic requirements of consumer products.

- Third, a fast response time, with no intermediate transmission link, allows motor power to be transmitted directly to the wheel, minimizing any perceived lag during acceleration.

However, the design principle of the hub motor determines its performance bottleneck:

First, the heat dissipation problem is prominent – the motor is built into the wheel set, and the heat generated during operation is difficult to dissipate quickly. Long-term high load (such as continuous climbing, high-speed driving) will cause the motor temperature to rise, triggering overheating protection, and then reducing the torque output (the torque of some products will drop by more than 30% when climbing), affecting the user experience.

Secondly, the weight distribution is uneven. The weight of the hub motor is concentrated on the wheel set, which will increase the rotational inertia of the wheel set, not only reducing the handling flexibility (such as requiring more force when steering), but also causing the wheel set to have excessive inertia when braking, increasing the braking distance.

Finally, the maintenance cost is high. If the motor fails, the wheel set needs to be replaced as a whole, and the cost is much higher than replacing individual components of the belt structure.

In general, both the belt structure and the hub structure are “compromise solutions” – the former sacrifices maintenance convenience in exchange for efficiency, and the latter sacrifices performance in exchange for integration. Under the comprehensive requirements of “high performance + low maintenance + excellent appearance”, both are difficult to meet the user’s experience expectations after the upgrade.

Trials and Limitations of Conventional Gearbox Motors (2016-2017)

As some users place higher demands on the power performance of electric skateboards (such as climbing torque and high-speed stability), the industry has begun to experiment with introducing “ordinary gearbox motors” – integrating cylindrical gearboxes commonly used in toy cars and small household appliances with motors, achieving “deceleration and torque increase” through gear meshing, in an attempt to break through the performance bottleneck of the belt and hub structure.

The core advantage of conventional gearbox motors is their significant torque boost through one or two stages of cylindrical gear reduction; motor torque can be amplified 3-5 times. This increases the climbing angle of some products from 15° with belt-type gearboxes to over 20°, meeting the demands of complex road conditions. However, this solution essentially involves the cross-application of low-performance technology for low-performance scenarios. Its design goals (low load, short life, and low noise sensitivity for toy cars) are fundamentally inconsistent with the actual requirements of electric skateboards (high load, long life, and low noise), leading to numerous unavoidable issues:

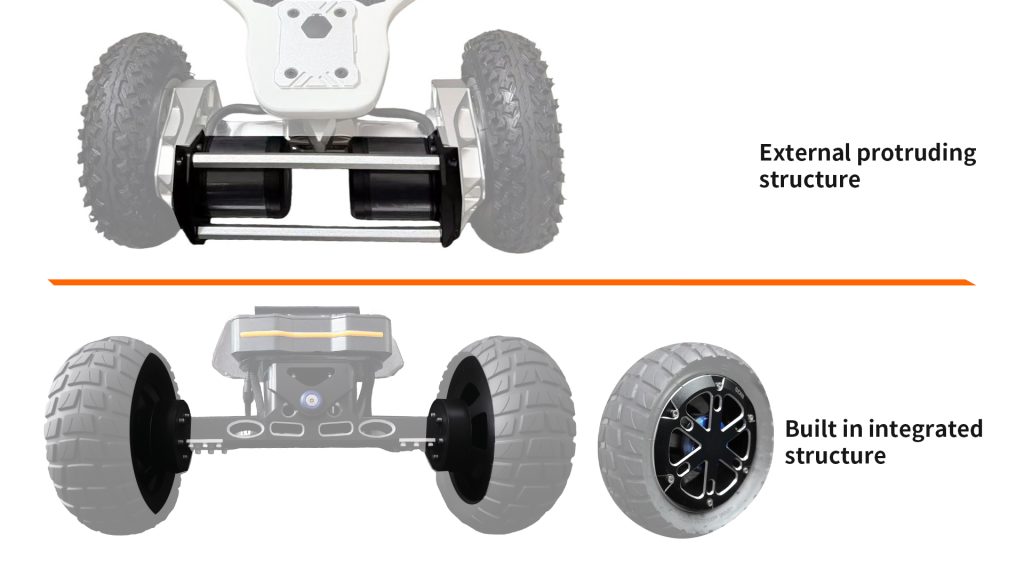

First, they’re too bulky and heavy. Conventional gearboxes use a “parallel axis cylindrical gear” structure, requiring the gears to be arranged axially. This results in a large overall size (typically exceeding 50mm in diameter). When integrated into a skateboard, this requires a protruding space below the board, which not only disrupts the skateboard’s flat appearance but also increases the risk of collisions (for example, the gearbox can easily strike bumps on the road surface while skating). Furthermore, the metal material of the gearbox increases the motor’s weight by over 40% compared to a belt motor, compromising the skateboard’s portability.

Second, noise and vibration (NVH) issues are prominent. Cylindrical gears mesh in “line contact,” and conventional gearboxes have low machining precision (pitch error is typically greater than 0.1mm). This easily generates “gear impact noise” during operation. No-load noise can reach over 60 decibels, and even higher under load, severely impacting the user experience. Furthermore, uneven gear meshing can cause motor vibration, which is then transmitted to the deck, reducing gliding stability.

Third, reliability and durability are poor. Electric skateboards are frequently subjected to bumps in the road (such as gravel roads and jointed roads). Conventional gearboxes have rigid connections between bearings and gears, lacking a buffer structure. These bumps can easily cause gear tooth wear and bearing loosening. Some products experience problems such as gear slippage and increased noise after just one to two months of use. Furthermore, gearboxes often have poor sealing, allowing dust and sand to easily enter, accelerating component wear and resulting in a lifespan far shorter than the expected six months or more.

Fourth, there’s a significant loss in efficiency. Conventional gearboxes have large meshing clearances (typically 0.1-0.2mm is allowed to prevent jamming) and high bearing friction, resulting in a transmission efficiency of only 70%-75%, compared to the 85%-90% of belt-type transmissions. This not only increases battery energy consumption (reducing battery life by 10%-15%), but also generates additional heat due to this efficiency loss, increasing the heat dissipation pressure on the motor.

The trial of ordinary gearbox motors has proved that simply “transferring” mature technologies in low-performance scenarios to electric skateboards cannot solve the core pain points of the industry. Instead, it will introduce new problems, prompting the industry to begin exploring power structures that are more suitable for the needs of electric skateboards.

The Introduction of Planetary Gear Structure (2017 to present)

In 2017, ECOMOBL broke through industry technological inertia and pioneered the crossover application of planetary gear structures, a technology used in high-end equipment such as aerospace, shipbuilding, and automotive, to electric skateboard powertrains, launching a solution with an integrated planetary gear motor. This innovation was not simply a technology transplant; rather, it addressed the core requirements of electric skateboards: limited space, high loads, and the need for both efficiency and quietness. By miniaturizing and optimizing the planetary gear structure, it completely resolved the multiple challenges inherent in traditional powertrains.

The core advantage of the planetary gear structure stems from its unique “multi-tooth meshing, coaxial transmission” design. Unlike the “parallel axes, line contact” of ordinary cylindrical gears, the planetary gear system consists of a sun gear (center gear), planetary gears (gears that rotate around the sun gear), and an internal ring gear (a fixed or rotating ring gear). After the motor power is transmitted to the sun gear, the planetary gears simultaneously rotate and revolve around the sun gear, ultimately outputting power to the wheel set through the planetary carrier. This structure is naturally adapted to the needs of electric skateboards:

From a performance perspective, the “multi-tooth simultaneous meshing” feature of planetary gears (usually 2-3 planetary gears mesh with the sun gear and the inner ring gear) greatly increases the transmission contact area. It can not only withstand higher loads (the torque carrying capacity is increased by more than 50% compared to the torque carrying capacity of cylindrical gears of the same volume), but also disperse the meshing pressure, reduce tooth surface wear, and improve durability. At the same time, multi-tooth meshing can offset the processing errors of individual gears, reduce vibration and noise, and the NVH performance is significantly better than that of ordinary gearboxes.

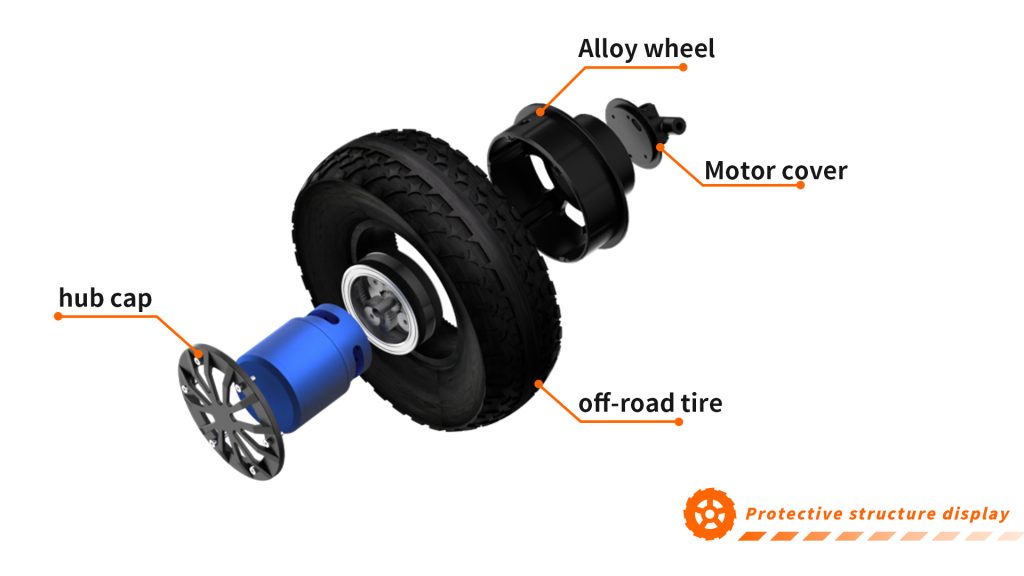

From a structural perspective, the planetary gear’s “coaxial transmission” design ensures that the power transmission path follows the same axis, and its overall volume is much smaller than that of a cylindrical gearbox with the same torque (under the same torque, the volume of the planetary gearbox can be reduced by 30%-40%). This enables the integration of “motor-gearbox-wheelset” without the need to reserve protruding space under the board, perfectly adapting to the flat appearance requirements of skateboards. In addition, the coaxial structure makes the weight distribution more concentrated, avoiding the “wheelset-heavy” problem of hub motors and improving sliding stability.

From the perspective of efficiency, the meshing clearance of the planetary gears can be controlled within 0.02-0.05mm through precision machining, and the rotation and revolution of the planetary gears can reduce friction resistance through needle bearings. The transmission efficiency can reach 90%-95%, which is not only higher than that of ordinary gearboxes but also better than belt structures (especially in high-load scenarios, belts are prone to slipping, while planetary gears have no sliding losses). It can effectively reduce battery energy consumption and improve battery life.

The launch of ECOMOBL’s built-in planetary gear motor marks the transition of electric skateboard power systems from “basic functional satisfaction” to a new stage of “co-optimization of high performance and user experience.” Its technical ideas have gradually been recognized by the industry and have become the mainstream design direction of mid-to-high-end electric skateboard power systems.

Core Transmission Principle Analysis: Conventional Gearbox vs. Planetary Gear

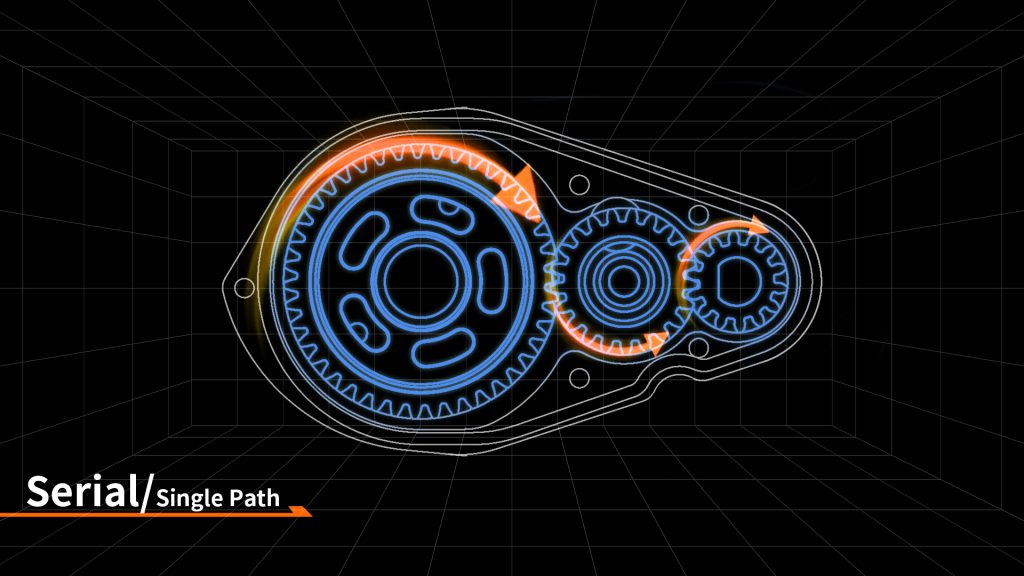

Ordinary Gearbox (Two-stage/Three-stage) -Tandem Single-path Transmission

Structural composition: Based on the series structure of “driving gear + driven gear”, the secondary transmission consists of two groups of gears of different sizes connected in series, and the tertiary transmission adds another group on this basis. The overall layout is linear, and all are external meshing transmissions.

Transmission Mechanism: Power is delivered from the motor through the first active/driven stage, the second active/driven stage (and one more stage in the third stage), and finally to the wheels. The power path is single and linear, like beads on a string.

Inherent limitations: Each additional transmission stage results in an additional meshing loss. Single-path transmission concentrates the load on a small number of gears, accelerating wear and reducing efficiency. A three-stage transmission is typically about 5%-8% less efficient than a two-stage one.

Schematic diagram of “series single path” transmission of an ordinary gearbox

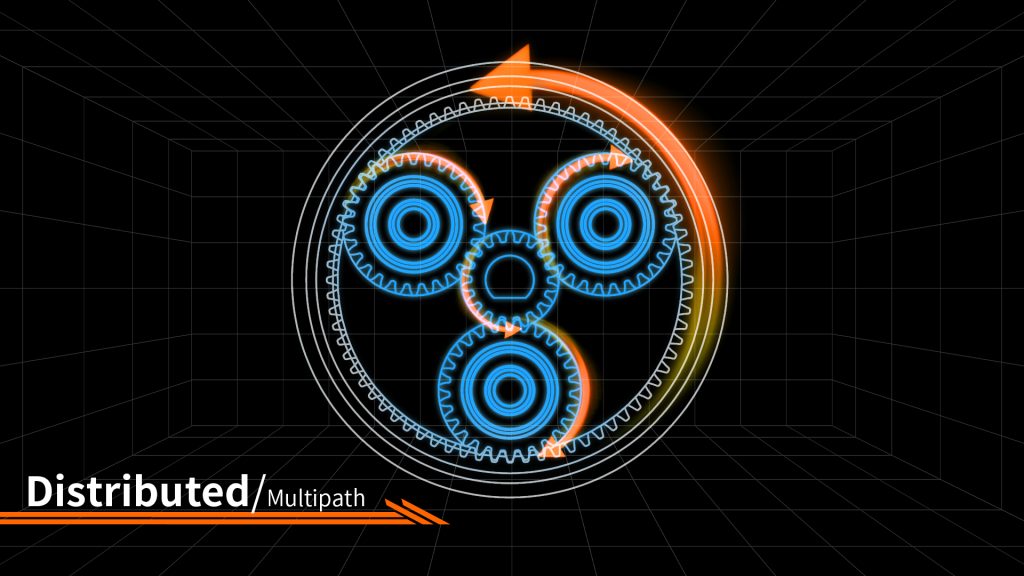

ECOMOBL Planetary Gear – Distributed Multi-path Transmission

Structural Composition

It consists of a central sun gear, three planetary gears, an inner ring gear, and a planetary carrier, forming a closed-loop structure of “many stars surrounding the moon”, which includes two types of meshing: external meshing (sun gear-planet gear) and internal meshing (planet gear-ring gear).

Transmission Mechanism

Power is input to the sun gear, driving the three planetary gears to rotate simultaneously. As the planetary gears orbit around the inner ring gear, they drive the planetary carrier, which in turn outputs power to the wheels. The three planetary gears are connected in parallel to share the load, and power is transmitted synchronously through multiple paths, achieving balanced and efficient results, like “many people working together to push a cart.”

Structural Advantages

Multi-tooth diversion reduces the load on a single gear, and the internal meshing contact area is larger. Combined with the symmetrical layout and reasonable transmission ratio, the system transmission efficiency can be stabilized at more than 95%; at the same power, the structural compactness is improved by about 50% compared with ordinary gearboxes.

Schematic diagram of the planetary gear “distributed multi-path” transmission.

Engineering Impact of Principal Differences

The “series single path” of ordinary gearboxes causes losses to accumulate with the number of stages, and the failure points are concentrated; the “distributed multi-path” of planetary gears achieves load dispersion and efficiency improvement, resulting in stronger output, longer li, and higher stability at the same power.

Multi-dimensional Comparison: Structure Equals Performance

Integration of Structure and Appearance

Ordinary gearboxes are mostly external protruding structures, which are easy to bump and damage the overall appearance; ECOMOBL planetary gears are built-in and integrated, with a simple appearance and stronger protection.

Durability and Maintenance

Planetary gears have more even force distribution, less wear, longer life, and more controllable maintenance cycles; traditional solutions have higher maintenance frequency in dusty and water-related environments.

Power and Energy Efficiency

Multi-tooth meshing and reasonable transmission ratio configuration bring stronger starting torque and climbing ability; under the same electrical energy input, the planetary gear system has higher actual output and better endurance performance.

NVH (Noise/Hardness)

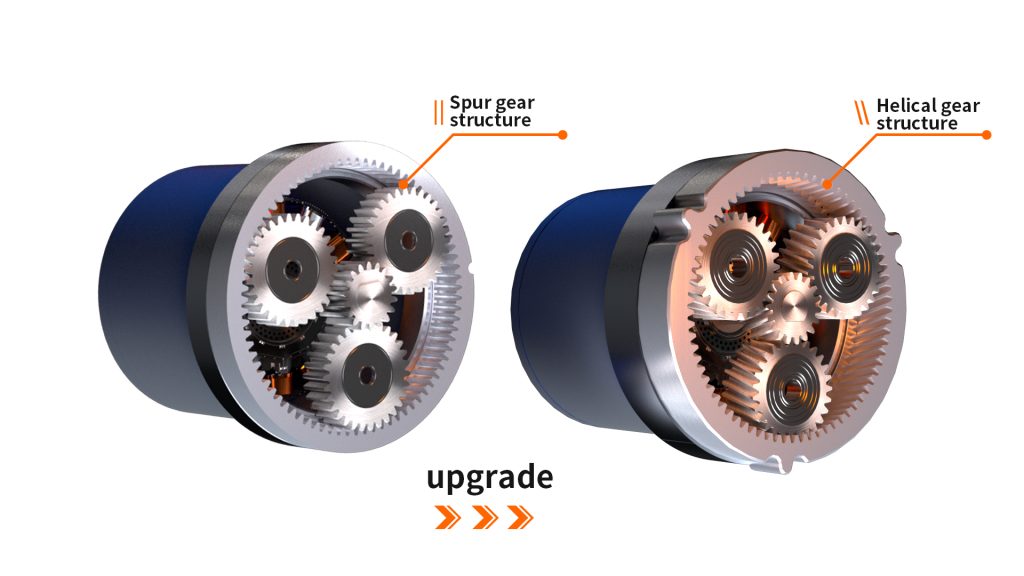

Market validation has shown that some conventional gearboxes address noise issues by replacing metal gears with plastic gears. ECOMOBL reduces meshing shock and noise sources through a “spur gear” to helical gear optimization approach. While the former involves a material compromise, the latter offers an upgraded transmission solution, resulting in a significant difference in durability and lifespan.

Material replacement ( plastic ) and solution upgrade (helical gear)

Security

The protruding structure of the external gearbox makes it more prone to collision and snag risks in off-road environments; the built-in integrated solution significantly reduces safety hazards and improves the structural strength of the entire board by converging external transmission parts.

Design Implementation and Application Suggestions

The planetary gear-based electric skateboard power system should be designed around integrated packaging, sealing protection, and heat dissipation paths. It should take into account load distribution, transmission ratio setting, and NVH control within a limited space. It should also integrate the overall board structure into an integrated appearance design to achieve both functionality and aesthetics.

User Value and Industry Significance

From the user’s perspective, planetary gears provide a “stronger, more stable, and quieter” riding experience and a “simpler and more rugged” appearance. From an industry perspective, this solution reshapes the technical route of electric skateboards with high-end dynamics ideas, pushing the product from “external assembly” to a systematic upgrade of “structure-appearance-experience.”

Final Thoughts

Compared to traditional belt, hub, and conventional gearbox solutions, planetary gears offer systemic advantages in transmission efficiency, compactness, integrated design, durability, and safety. The ECOMOBL’s internal planetary gear motor utilizes a distributed multi-path transmission system, achieving more efficient and reliable power output. Its integrated design unifies aesthetics and engineering. This approach provides a verifiable engineering reference for the future evolution of electric skateboard powertrains.